Here is the title one h1 placeholder text

Manufacturing capacity

Injection moulding

20+ sets of full computer-controlled injection moulding machines including 2K injection moulding machine with tonnage from 280T to 3200T.

Full ranges of plastic accessories in all different dimensions : Front & rear bumper, side step, body kit, side molding, front grille, roof spoiler, head lamp etc.

Central feeding system and robot arm pick-up facilitate the efficient and stable production processes.

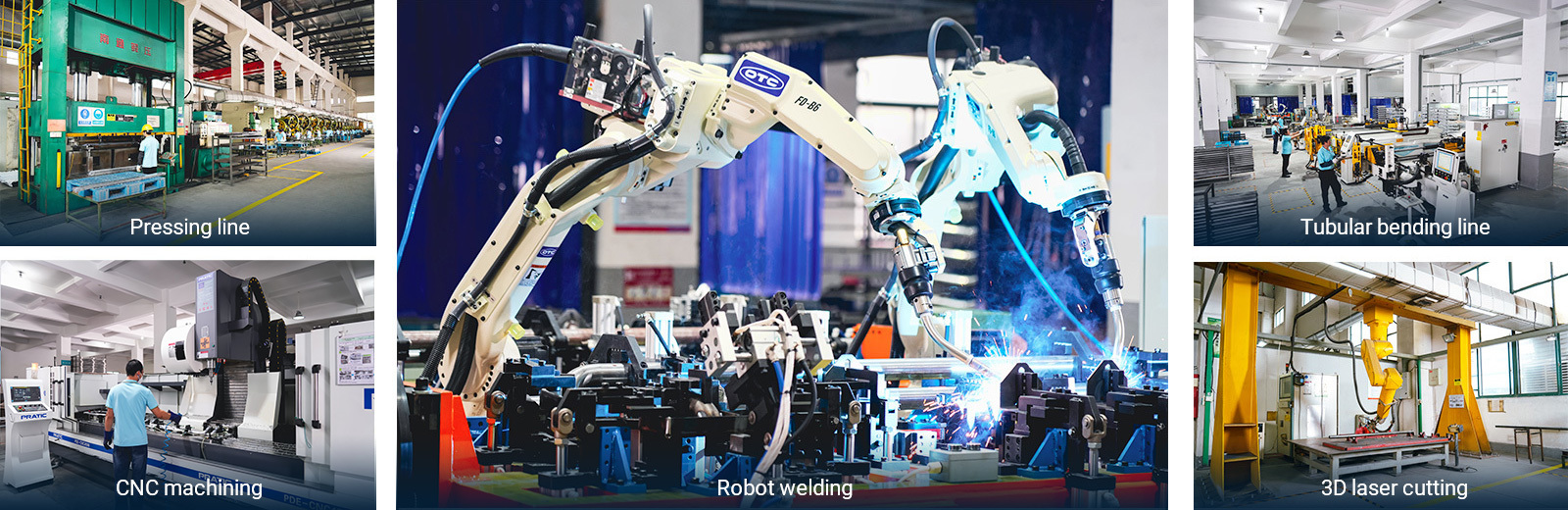

Metal parts processing

90% manufacturing processes are done in house by various of advanced and automated machines that can ensure the criterion of strength, accuracy, appearance quality with good cost efficiency.

Manufacturing capabilities covers all kinds of metal parts made from different material that with geometrical shape such as bull bar, sport bar, fender flare, roof rack, side bar, tow bar, cross bar etc.

Surface coating

Key surface coating for end products are done in house for better control of the surface quality and performance of the products.

Robot painting, semi-automatic and manual painting can be chosen base on the volume of the products for good cost efficient.

Cooperated with famous material manufacturers : Tiger, Akzo Nobel, Onwings etc.

|

Spray painting line

|

Powder coating line

|

Assembly line

Automatic conveyor belt used to streamline processes and enhance productivity.

Poka yoka solution applied to key process.

SOP & SIP in place for each work station to standardize production processes which can reduce the defective and scrap ratio.

Contact Information

Address: No.16, Shunyang Road, Menghe Town, Xinbei District, Changzhou City, Jiangsu Province

CopyRight©2024 CHANGZHOU HUAJIA VEHICLE INDUSTRY CO.,LTD. (CNT)

Powered by: www.300.cn | Tags

微信公众号

微信公众号